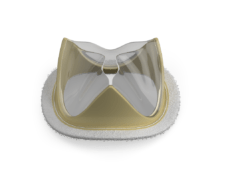

Results from the first animal study of the Tria transcatheter aortic valve (Foldax) have been presented at CRT 2022 (26 February–1 March, Washington DC, USA). The transcatheter Tria valve is the third device being developed by Foldax, with the company’s aortic surgical and mitral surgical valves currently being studied in humans.

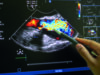

Investigators for the pilot study of four ovine subjects reported “the Tria valve demonstrated satisfactory deployment, function and good haemodynamic results. There was no pannus, calcification or thrombosis on leaflet surfaces (out to as long as 90 days post-implantation).” Results were presented by Steven J Yakubov (Riverside Methodist Hospital, Columbus, USA).

On the basis of this pilot study, Foldax plans to conduct a larger pre-clinical study of its transcatheter valve in 2022 intended to support a first-in-human study.

“Expanding TAVI into young patients requires enhanced haemodynamics and durability with greater life expectancy. In this small animal study, we found that the TRIA transcatheter biopolymer valve showed promising haemodynamic results with encouraging durability,” said Yakubov. “Having a TAVI that can last the lifetime of a younger patient is something we need in cardiovascular medicine and it will be exciting to see outcomes from this valve as it moves into humans.”

Foldax said it intends to develop surgical and transcatheter valves designed to last a lifetime addressing the historical tradeoffs between tissue and mechanical valves. The Tria valve platform combines the company’s proprietary LifePolymer with a design intended to resist calcification, withstand stresses and strains without failure, and restore patient quality of life without requiring lifelong use of anticoagulants.

The company’s Tria aortic surgical valve has been studied in humans out to two years. One-year results for the aortic surgical valve recently published in JACC: Cardiovascular Interventions showed that it met all of its primary endpoints, including valve effective orifice area (EOA) and clinically significant improvement in New York Heart Association (NYHA) class.

“In the process of making a better valve, we will also be changing the face of the heart valve industry. The Company is democratising the manufacturing of heart valves by eliminating the need for a central large skilled human workforce and replacing it with a small footprint robotic manufacturing pod that can be placed in any region of the world. We are not only solving historical problems with both tissue and mechanical valves, but also making valve manufacturing incredibly efficient and accessible,” said Foldax CEO Frank Maguire.

I am from India, I have mitral valve prolaps, modret regurgitation since 2years . Can I know when the Foldax heart valves come in to the market please inform me thank You very much sir