The donation of new 3D printing technology to the Visible Heart Laboratories at the University of Minnesota (Minneapolis, USA) will aid the training of future cardiologists and medical device development by producing anatomic models that replicate a patients’ heart anatomy and pathology.

Stratasys is sponsoring the University of Minnesota Visible Heart Laboratories with a donation of Stratasys J750 Digital Anatomy 3D printers, as well as MakerBot Method X and MakerBot Sketch 3D printers. The Visible Heart Laboratories are a research lab located that supports medical research, student and physician education, and medical device product development and testing.

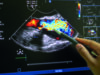

Stratasys’ Digital Anatomy 3D printers produce anatomic models that mimic the feel, responsiveness, and biomechanics of human anatomy. Models can be punctured, sutured, cut, and physically manipulated like human tissue.

During their education, all University of Minnesota medical students pass through the Visible Heart Laboratories to learn about the benefits of 3D printing technology and how anatomic models can assist them in their future practice. The Visible Heart Laboratories also are committed to providing outreach education about cardiac anatomy and device therapy to students from middle school age to clinical cardiologists.

“The Visible Heart Laboratories are driven to train the next generation of medical device developers and provide them with the abilities to 3D print prototypes and/or virtually placed devices within real heart anatomies, as today these are considered essential skills,” said Paul Iaizzo, professor Visible Heart Laboratories, University of Minnesota Medical School.

In addition to medical student, patient, and physician education, the 3D printing technology in the Visible Heart Laboratories supports medical device research across a variety of coronary medical device applications. 3D printing technology allows physicians, researchers, and medical device product developers to iterate, create, and test existing and new medical devices in anatomic models that mimic actual anatomy and pathology.

“We believe that widespread use of 3D printed anatomic models in healthcare would translate into better and more cost-effective patient care and shorter time to market for new medical device innovations. This sponsorship allows us to support the world-class education and medical device research happening right here in Minnesota,” said Rich Garrity, president, Americas for Stratasys. “At Stratasys, we recognize the importance of supporting the communities in which we live and work, and we are proud to support the University of Minnesota Visible Heart Laboratories and the work they are doing.”